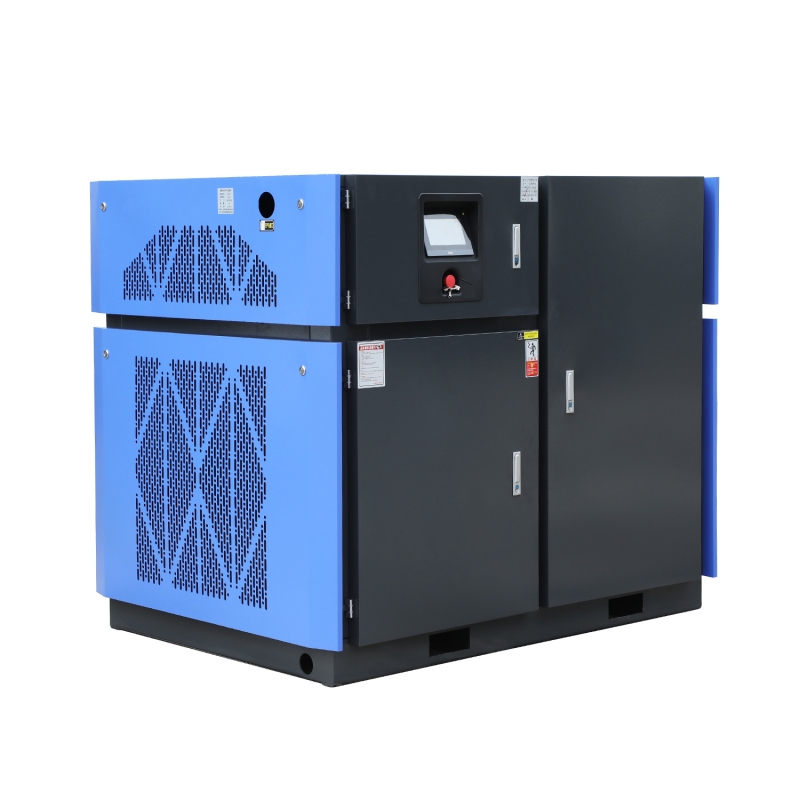

Kab rov tav ob-theem siab ntsia hlau cua compressor Ob theem ntsia hlau Cua Compressor Electric Ntsia Hlau Cua Compressor Nqe

| Qauv | TSVII-22A | TSV II-37A | TSVII-45A | TSVII-55A | TSVII-75A | TSVII-90A | TSVII-110A | TSVII-132A | |

| Cua ntws / siab (M3 / min / Mpa) | 4.1/0.7 | 6.9/0.7 | 8.9/0.7 | 11.2/0.7 Nws | 15.1/0.7 Nws | 20.0/0.7 Nws | 22.0/0.7 Nws | 26.0/0.7 Nws | |

| 4.0/0.8 | 6.8/0.8 | 8.8/0.8 | 11.0/0.8 Nws | 15.0/0.8 Nws | 19.8.00 Nws | 21.2/0.8 Nws | 25.8.00 Nws | ||

| 3.4/1.0 | 6.2/1.0 | 7.8/1.0 | 9.7/1.0 | 12.4/1.0 Nws | 17.9/1.0 Nws | 19.8/1.0 Nws | 23.5/1.0 Nws | ||

| Cua muab kub | ≤ambient kub +8 ~ 15ºC | ||||||||

| Lub cev muaj zog | Lub zog (kw / hp) | 22/30 ib | 37/50 ib | 45/60 ib | 55/75 ib | 75/100 ib | 90/120 ib | 110/150 ib | 132/175 ib |

| Pib txoj kev | VSD pib | ||||||||

| Qhov hluav taws xob (v / hz) | 380V 3PH 50HZ / lwm yam voltagesd tuaj yeem kho tau) | ||||||||

| Tsav txoj kev | intergrade cua kawg thiab lub cev muaj zog | ||||||||

| Cov ntsiab lus roj (PPM) | ≤ 3 | ||||||||

| Connector nti | 1" | 1 1/2 " | 2" | 2" | 2" | 2 1/2 " | 2 1/2 " | 2 1/2 " | |

| Dimension | ntev mm | 1254 ib | 1455 | 1754 ib | ib 7854 | Xyoo 1914 | 2454 ib | 2454 ib | 2454 ib |

| dav mm | 900 | 1100 | 1200 | 1300 | 1300 | 1500 | 1500 | 1500 | |

| qhov siab mm | 1190 ib | 1300 | 1550 | 1550 | 1600 | 1840 | 1840 | 1840 | |

| Qhov hnyav (kg) | 450 | 580 | 925 ib | 970 ua | 1170 ib | 1746 ib | 1750 | 1790 ib | |

1. Kev lag luam hluav taws xob hluav taws xob, kev ntsuas, kev tshem tawm cov hmoov tshauv, lub Hoobkas lwm yam compressed cua tshuab, dej kho nrog boiler pub dej kho thiab kev kho dej khib nyiab, thiab cov chaw siv hluav taws xob yuav muaj cov tshuab cua compressed rau cov khoom siv fais fab.

2. Tshuaj fiber ntau kev lag luam, paj rwb spinning kev lag luam;chemical fiber kev lag luam feem ntau yog siv roj rau instrumentation thiab suction phom, luam ntawv thiab dyeing mas siv roj rau lub hwj chim thiab instrumentation.

3. Metallurgical kev lag luam, muab faib ua hlau thiab hlau kev lag luam thiab tsis-ferrous hlau smelting thiab manufacturing kev lag luam.

4. Hauv kev lag luam aerospace, vim tias cov khoom siv pneumatic tuaj yeem tiv taus hluav taws xob thiab kub kub, lawv tuaj yeem tiv taus qhov nrawm nrawm, yog li lawv tau siv dav hauv kev tswj cov dav hlau niaj hnub, foob pob hluav taws, thiab cuaj luaj.

4. Hauv kev lag luam hlau thiab hlau, nws yog siv los ua cov khoom siv roj rau cov cuab yeej siv hluav taws xob thiab cov cuab yeej pneumatic, cov pa roj, qhov chaw tu, thiab cov hlau tsis muaj hlau smelting.

5. Nws yog siv rau hauv kev siv roj-pab txhaj tshuaj molding tshuab hauv kev txhaj tshuaj molding kev lag luam.

6. Hauv kev lag luam iav, nws yog siv rau rov qab tshuab ntawm cov hnab ntaub los yog lim cartridges rau cov khoom siv plua plav xws li iav khoom siv plua plav collectors thiab cov lim cua ntawm tus kheej.

7. Electronics, thwmsim, thiab precision ntsuas kev lag luam.

8.Lwm kev lag luam: tsheb tsim, ore mining, chaw ua si loj, thiab lwm yam.

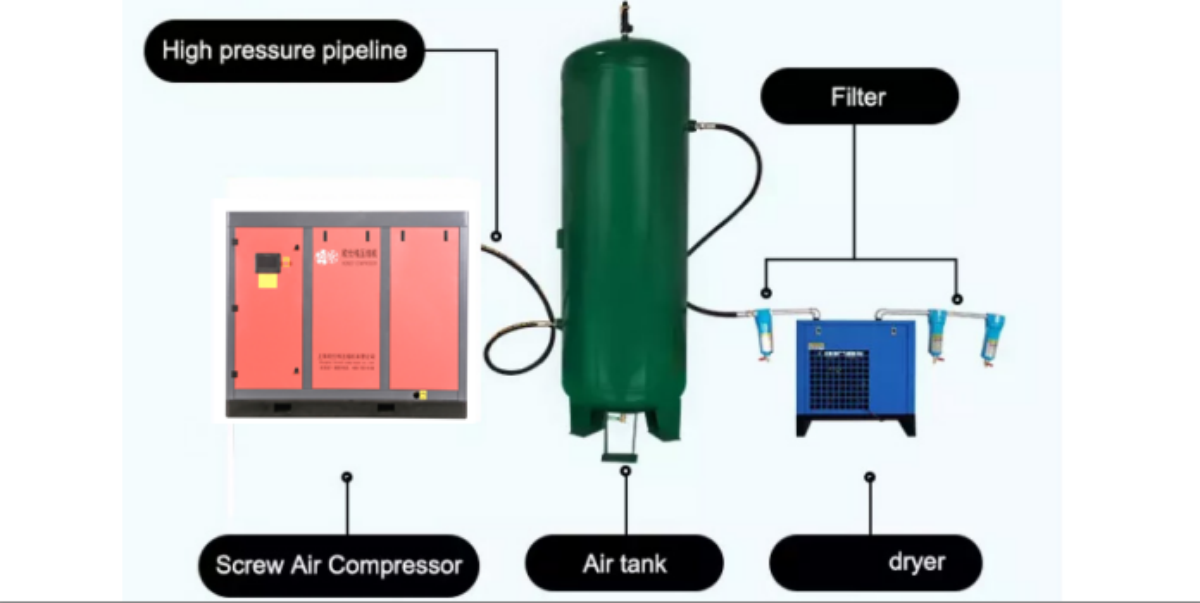

Cua compressor < ValveAir < tank < FilterAir < tshuab ziab khaub ncaws < Filter < Filter < Filter