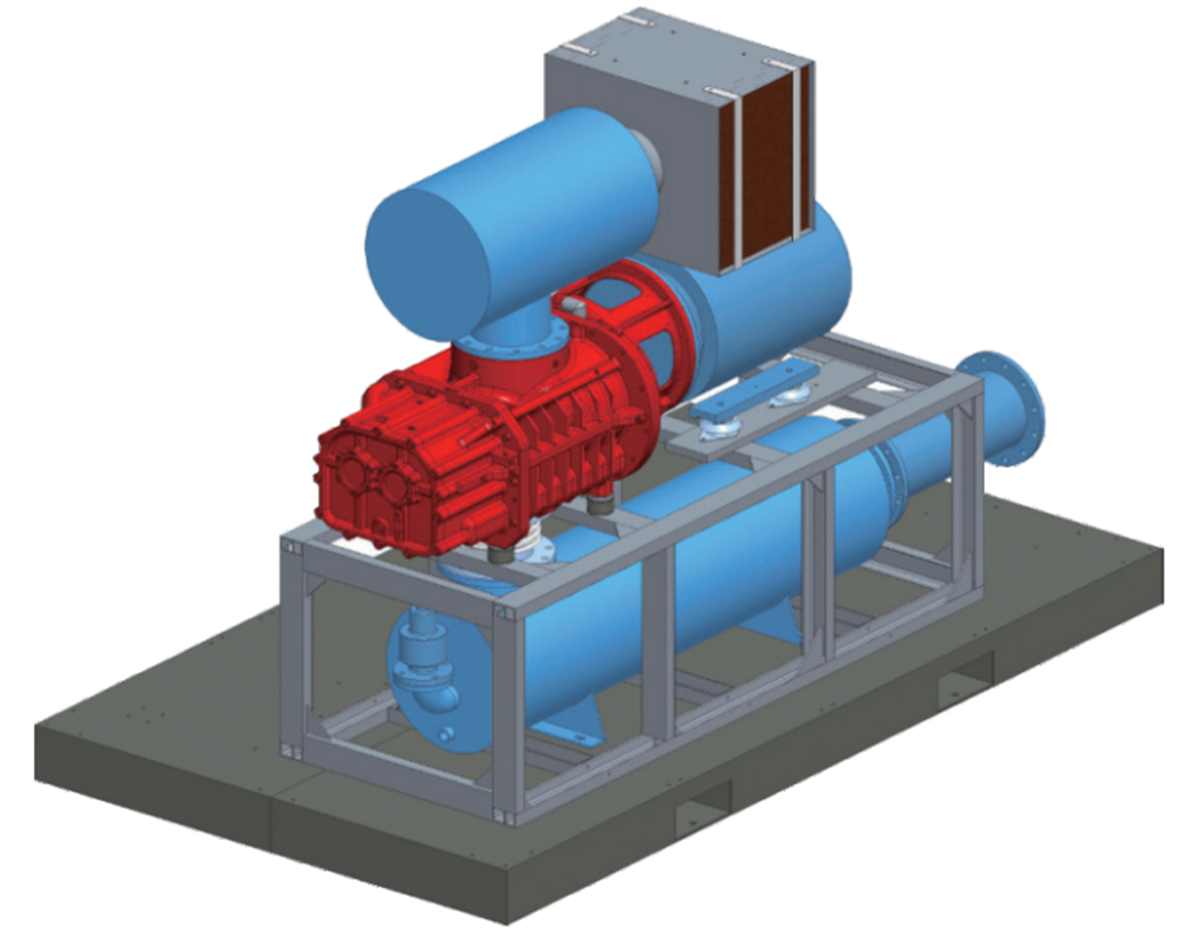

Muaj Roj Dawb Vsd Ntsia Hlau Cua Blower / Nqus Twj Nrog Inverter thiab Pm Tsav

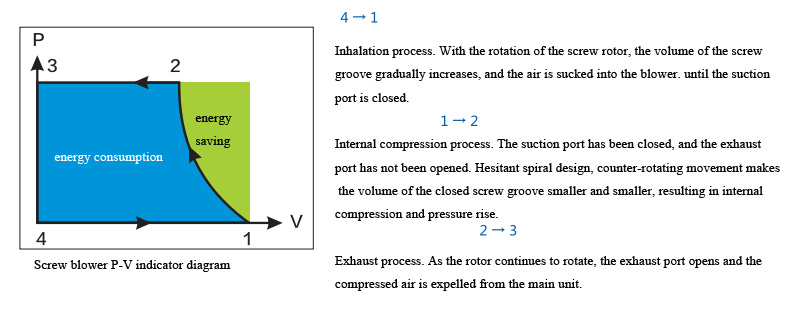

Nyob rau hauv tib lub ntim thiab huab cua siab, lub zog noj yuav tsum tau los ntawm cov ntsia hlau blower yog ntau me me.Qhov ntsuab hauv daim duab yog kev txuag hluav taws xob noj.Piv nrog rau cov tsoos Roots blower, cov ntsia hlau blower yuav txuag tau li 35%, qhov siab dua, qhov tseem ceeb ntawm lub zog txuag, thiab qhov nruab nrab lub zog txuag yog 20%.Lub zog txuag ntawm roj-dawb blower tuaj yeem ncav cuag 20% -50%.

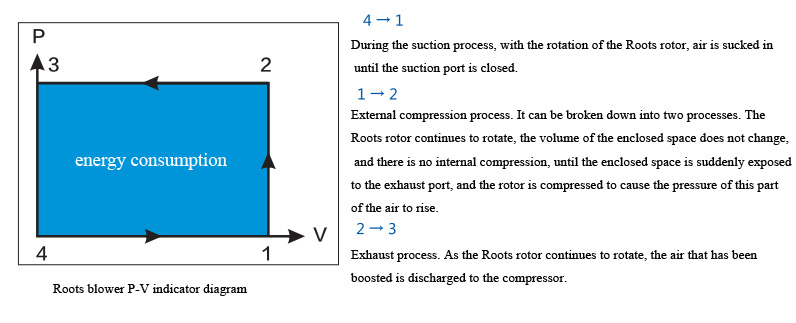

Lub hauv paus blower tsis muaj compression sab hauv, yog li thaum lub tso pa tawm, cov cua siab dua nyob rau hauv cov yeeb nkab network yog reversely them rov qab mus rau hauv lub compression chamber, tsim cov roj ramming, uas ua rau lub suab nrov tsawg-zaus huab cua, thiab kev co. cov khoom siv kuj yog loj heev, uas zoo heev txo lub siab ntawm cov ntsia hlau kiv cua.Txo suab nrov thiab kev vibration, 15-30dB qis dua hauv paus tshuab suab nrov (A)

1. Kev kho dej phwj tuaj

Txawm hais tias nws yog cov dej phwj hauv nroog lossis cov dej phwj hauv tuam txhab (xws li textile printing thiab dyeing, tawv, tshuaj, tshuaj lom neeg kev lag luam, ntawv ua, yug me nyuam thiab slaughtering, thiab lwm yam), nws yuav tsum tau kho raws li tus qauv ua ntej nws yuav muab tso rau hauv lub ntuj dej. los yog siv dua.Hauv cov txheej txheem dej phwj tuaj, qhov txuas tseem ceeb yog cov khoom siv oxygen rau kev kho mob lom, uas yog, qhov txuas aeration.Thaum lub sijhawm ua haujlwm ntawm ntau cov txheej txheem dej phwj tuaj kho cov nroj tsuag, kev siv lub zog ntawm cov pa oxygen rau kev kho mob lom rau 50% -55% ntawm lub zog noj ntawm tag nrho cov nroj tsuag.Muaj ntau chav rau kev txo qis kev noj cov tshuaj lom neeg cov pa oxygen mov system.Xaiv lub tshuab ua haujlwm tau zoo yuav ua rau muaj txiaj ntsig kev lag luam ncaj qha.

2. Pneumatic conveying-dilute theem-hmoov conveying hauv cement cog-hmoov conveying hauv petrochemical kev lag luam

Cov nqi hluav taws xob qis dua (txog 80% ntawm cov nqi siv hluav taws xob hauv lub neej), kev siv lub tshuab ua haujlwm tshiab uas ua rau lub sijhawm poob qis rau kev saib xyuas.

3. Fermentation

Cov nqi qis zog (txog li 80% ntawm cov nqi siv hluav taws xob hauv lub neej), lub tshuab ntsia hlau tshiab tshiab rau kev saib xyuas qis qis, tsis tshua muaj dej ntws thiab siab ua haujlwm ntau yam Nonwoven ntau lawm, huab cua riam, texturing txaus kho kom muaj zog fiber ntau, lub zog txuag hluav taws xob muaj peev xwm ntawm kev ua haujlwm tas li 24/7 nrog cov nqi khiav haujlwm qis.Point-of-use installation tsis muaj suab nrov tiv thaiv ntsuas.

4. Desulfurization thiab denitrification

Hauv kev tsim hluav taws xob hluav taws xob, hlau, iav, tshuaj thiab lwm cov chaw tsim khoom, ntau lub boilers raug hlawv, thiab cov pa hluav taws xob tawm los ntawm lawv muaj ntau cov sulfur, nitrate thiab lwm yam khoom, uas ua rau cov huab cua phem heev.Qhov no yuav tsum muaj kev kho mob xws li desulfurization thiab denitrification ua ntej tso tawm, thiab tsuas yog tso tawm rau hauv qhov chaw tom qab ncav cuag tus qauv.Nyob rau hauv desulfurization thiab denitrification chaw, roj-dawb ntsia hlau blowers yuav tsum tau oxidation kiv cua.